The emergence of 3D printed open-source lathes marks a significant milestone in the development of cost-effective machine tools. By ingeniously combining 3D printing technology with concrete casting techniques, you can now construct a robust mini lathe at a fraction of the cost of traditional manufacturing methods. This innovative project is designed to be highly accessible, requiring minimal tools and materials, making it an ideal venture for hobbyists, DIY enthusiasts, and small-scale manufacturers alike.

Imagine a world where creating your own machine tools is as simple as hitting ‘print’ on your 3D printer. For many hobbyists and DIY enthusiasts, this isn’t just a dream—it’s becoming a reality. With the advent of 3D printed open source lathes, the barriers to entry for precision manufacturing are rapidly dissolving. This project ingeniously marries the precision of 3D printing with the robustness of concrete casting, allowing you to construct a durable mini lathe at a fraction of the cost of traditional methods.

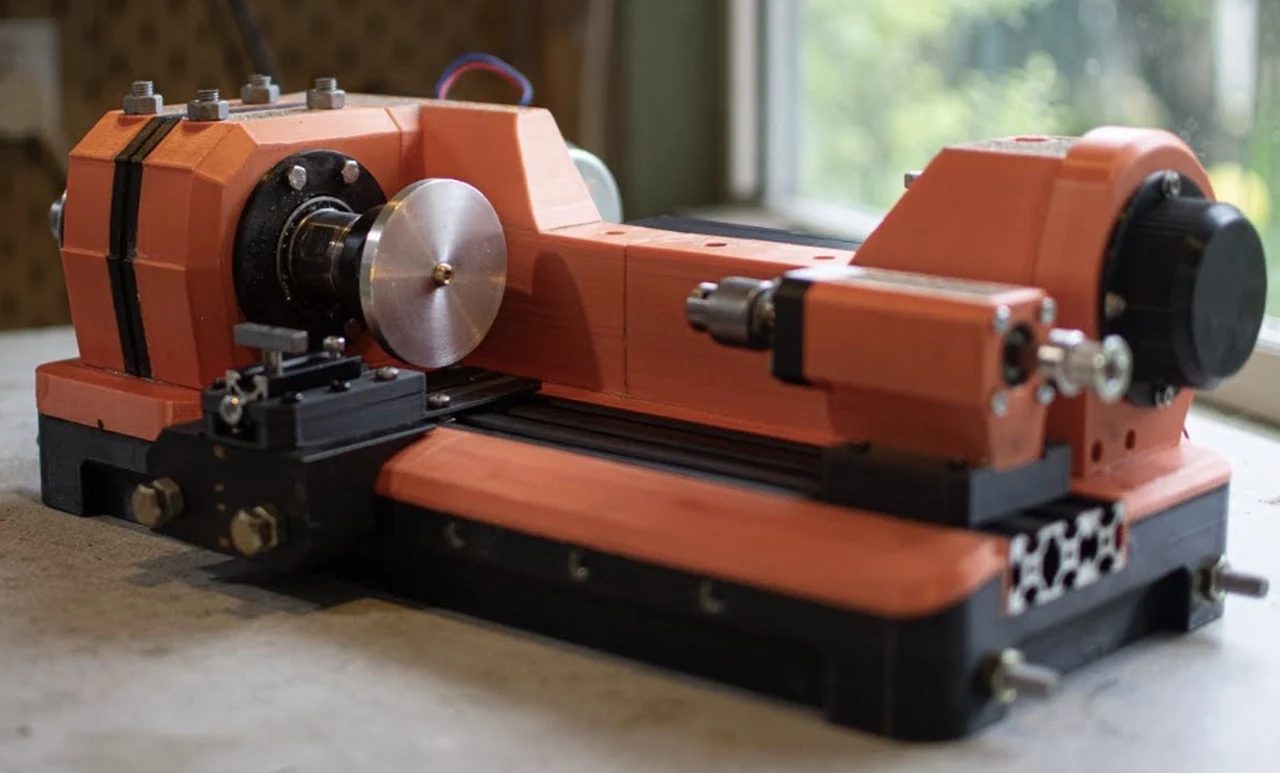

3D Printed Workshop Lathe

TL;DR Key Takeaways :

- The 3D printed open-source lathe project integrates 3D printing with concrete casting to create a cost-effective and durable mini lathe, ideal for hobbyists and DIY enthusiasts.

- The lathe’s design is simple and efficient, requiring minimal tools and materials for construction. The design includes three key components: the base, headstock, and concrete pour.

- The assembly process involves installing non-printed hardware and threading options on the base, with the headstock designed as a separate, replaceable component. The concrete pouring process requires precise alignment and surface finishing.

- Basic tooling for the lathe includes gravers, with instructions provided for grinding them to a diamond shape. The lathe’s capabilities are demonstrated through a challenging aluminum turning task.

- The estimated cost of the project ranges from 100 to 150 Australian dollars (66 to 100 US dollars), making it an economical choice for machine tools. The project lays a foundation for future enhancements and innovations in the field of DIY machine tools.

The journey to this breakthrough wasn’t without its challenges. Initial designs, while ambitious, didn’t quite hit the mark in terms of performance and durability. But instead of a setback, this prompted a creative reimagining of the project, leading to a more reliable and functional design. This iterative process highlights the power of blending modern technology with traditional materials, crafting a tool that is not only cost-effective but also capable of handling demanding tasks. As you read on, you’ll discover how this project not only enables individuals to create their own tools but also invites a community-driven approach to innovation and improvement.

Innovative Concept and Iterative Development

The genesis of this project lies in the novel idea of using 3D printed molds filled with concrete to create sturdy, reliable machine tools. Initial prototypes, while promising, fell short of expectations in terms of performance and durability. This setback, however, spurred a comprehensive redesign process aimed at enhancing reliability and functionality. The iterative development journey underscores the immense potential of blending innovative technology with traditional materials to craft innovative, practical solutions.

- Concept originated from combining 3D printing with concrete casting

- Initial prototypes prompted redesign for improved performance

- Iterative process highlights the fusion of modern and traditional techniques

Streamlined Design and Efficient Construction

The lathe’s design philosophy prioritizes simplicity and efficiency without compromising on functionality. To embark on this project, you’ll need a basic set of tools including:

- 3D printer

- Hacksaw

- Spanner

- Screwdrivers

- Concrete vibrator

The construction process is methodically divided into three key components: the base, headstock, and concrete pour. Threaded rods, coupling nuts, and 2020 aluminum extrusion play crucial roles in the assembly, making sure a robust and stable structure. The incorporation of tapered roller bearings enhances performance and longevity, reflecting a well-thought-out design that balances cost-effectiveness with quality.

3D Printed Open Source Lathe Project

Discover other guides from our vast content that could be of interest on 3D Printing.

Detailed Assembly Process

Assembling the lathe involves a series of precise steps, each critical to the machine’s overall performance:

1. Install non-printed hardware on the base, making sure proper alignment.

2. Thread options are provided for customization based on available materials.

3. The headstock is designed as a separate, replaceable component, facilitating future upgrades or repairs.

4. The concrete pouring process requires meticulous attention to alignment and surface finishing to guarantee accuracy and stability.

This methodical approach ensures that the resulting lathe is not only functional but also durable and capable of precision work.

Tooling and Practical Applications

The basic tooling for the lathe includes gravers, with detailed instructions provided for grinding them to achieve the optimal diamond shape. An adjustable tool rest is incorporated into the design, though initial tasks may require a temporary rest solution. The lathe’s capabilities are put to the test through a challenging aluminum turning task, demonstrating its robustness and versatility in handling various materials and complexities.

Performance Evaluation and Cost-Efficiency Analysis

Rigorous testing reveals the lathe’s impressive ability to handle demanding tasks with precision. While suggestions for improvements in tool materials are noted, the overall performance is highly commendable, especially considering its cost-effective nature. The estimated cost for constructing this lathe ranges from 100 to 150 Australian dollars (approximately 66 to 100 US dollars), positioning it as an extremely attractive option for those seeking economical yet capable machine tools.

Future Prospects and Community Engagement

This 3D printed open-source lathe project not only offers a practical solution for affordable machining but also lays a solid foundation for future enhancements and innovations in DIY machine tools. The creator expresses satisfaction with the design’s performance and actively encourages feedback from the community for further development. This open approach fosters a collaborative environment where improvements and adaptations can be shared, potentially leading to even more advanced and accessible machine tool designs.

- Project serves as a springboard for future innovations in DIY machine tools

- Community feedback is encouraged to drive continuous improvement

- Potential for adaptations and enhancements in future iterations

By providing widespread access to access to machine tools, this project enables individuals and small businesses to engage in precision manufacturing and prototyping. The combination of 3D printing technology with traditional materials opens up new possibilities for creating cost-effective, customizable machinery. As this technology continues to evolve, we can anticipate even more sophisticated and accessible DIY machine tools, further transforming small-scale manufacturing and hobbyist engineering.

Media Credit: Chris Borge

Filed Under: Design News, DIY Projects, Guides

Latest TechMehow Deals

Disclosure: Some of our articles include affiliate links. If you buy something through one of these links, TechMehow may earn an affiliate commission. Learn about our Disclosure Policy.