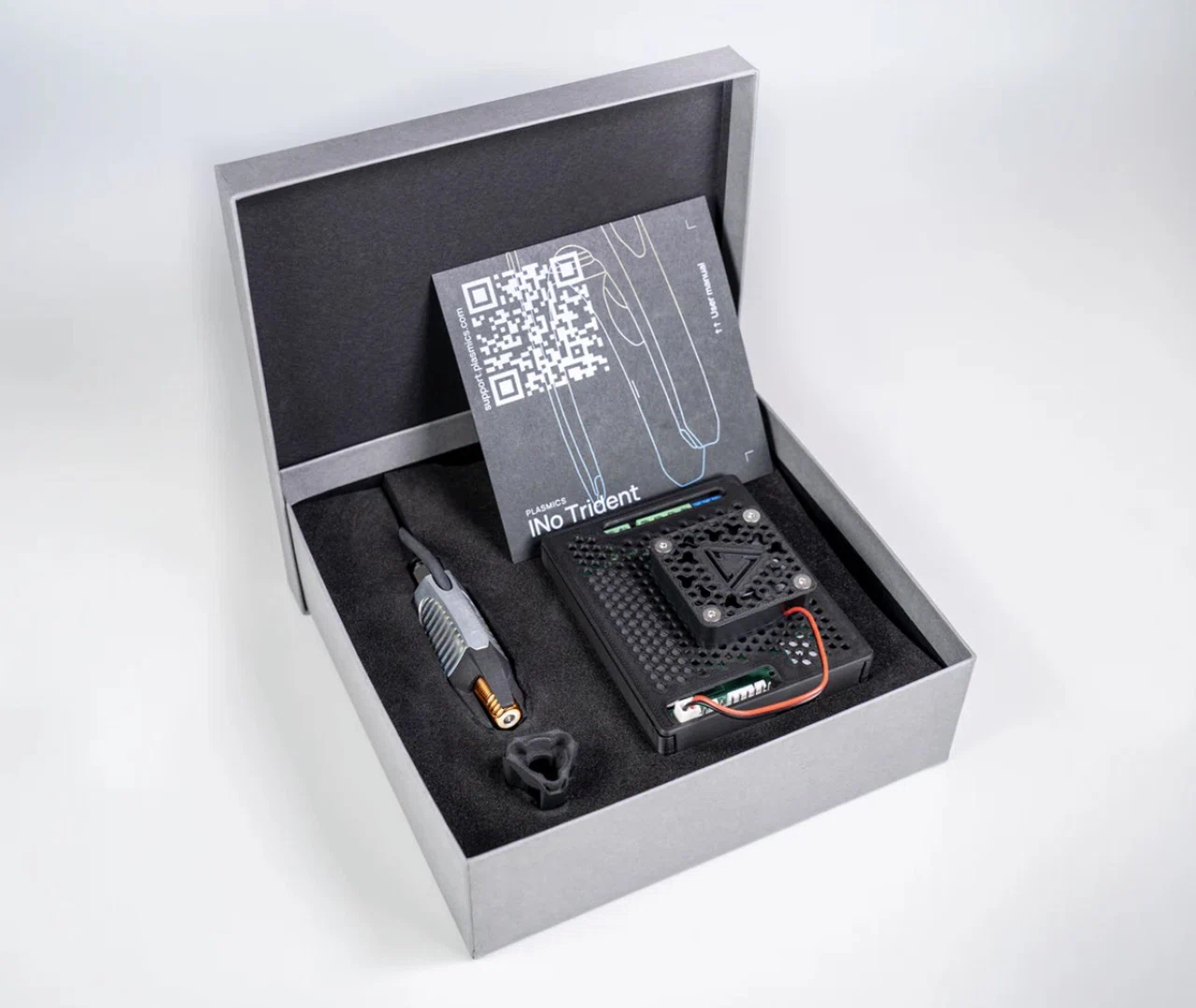

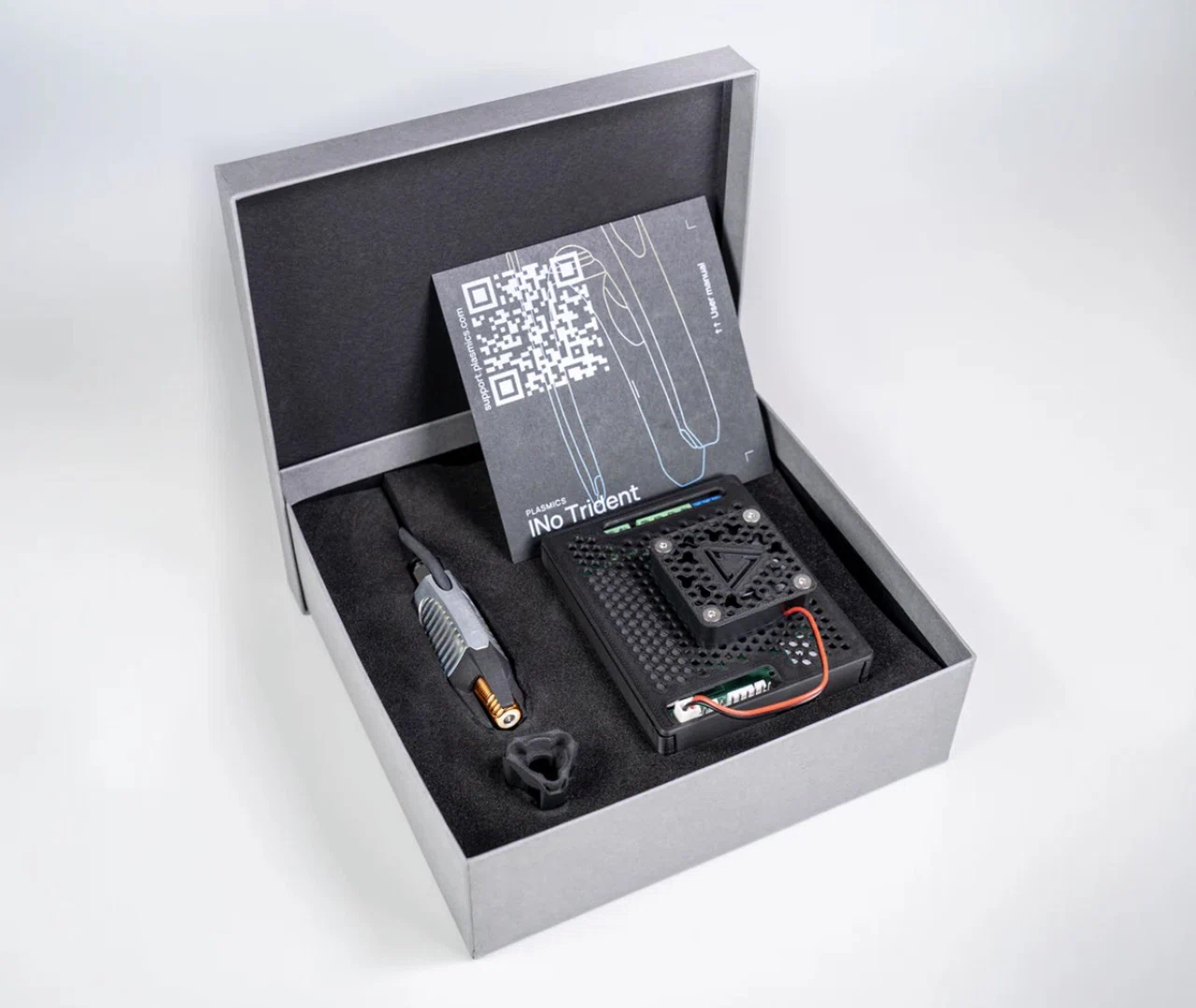

Most 3D printing enthusiasts have encountered quality issues during their printing journey. Halfway through a complex project, problems such as sagging bridges, uneven surfaces, or inconsistent filament heating can disrupt progress. These challenges often leave users frustrated, feeling limited by the technology when striving for precision and creativity. However, what if you could address these obstacles and make your printer smarter, faster, and more adaptable to the demands of your designs? The Ino Trident inductive hotend by Plasmics may offer the solution priced at £339.

The Ino Trident by Plasmics represents a significant advancement in 3D printing as the first commercially available inductive hotend. Unlike traditional hotends that rely on resistive heating elements, this innovative design uses electromagnetic induction for faster, more precise, and energy-efficient temperature control. By incorporating a slim metal tube as the heat block, the Ino Trident achieves rapid heating and cooling, enabling intricate, higher-quality prints. This innovation not only enhances performance but also introduces greater efficiency and adaptability to the printing process.

At its heart, the Ino Trident introduces inductive heating, a departure from traditional resistive methods. Electromagnetic induction heats the filament with greater speed and precision, allowing faster temperature adjustments, improved print quality, and the capability to handle intricate designs. While still in its early stages, the hotend has already demonstrated significant potential to address common 3D printing challenges. Let’s explore how this new technology works and what it could mean for your future projects.

How Electromagnetic Induction Transforms 3D Printing

TL;DR Key Takeaways :

- The Ino Trident by Plasmics is the world’s first inductive hotend for 3D printing, using electromagnetic induction for faster, more precise, and energy-efficient temperature control compared to traditional resistive heating.

- Electromagnetic induction enables near-instantaneous temperature changes, improving responsiveness for complex geometries, multi-material prints, and intricate designs.

- Key benefits include improved support structures, seamless variable temperature printing, and enhanced filament heating efficiency, resulting in higher-quality and more reliable prints.

- Challenges include slicer software compatibility, inconsistent filament heating at higher flow rates, and the need for workflow simplification to make the technology more accessible.

- The Ino Trident has the potential to redefine 3D printing standards, with future advancements in software and hardware expected to unlock its full capabilities for both hobbyists and professionals.

At the core of the Ino Trident lies the principle of electromagnetic induction, a method that fundamentally changes how heat is generated in 3D printing. Traditional hotends rely on resistive heating elements to transfer heat to the filament, a process that can be slow and inefficient. In contrast, the Ino Trident generates heat directly within the metal heat block through electromagnetic currents, allowing for near-instantaneous temperature adjustments.

This capability translates into a more responsive system, particularly beneficial for intricate printing scenarios. Whether you’re working with multi-material prints, complex geometries, or challenging designs, the Ino Trident provides enhanced control and precision. Its ability to adapt quickly to changing temperature requirements ensures smoother transitions, reduced defects, and improved overall print quality.

Key Advantages of Inductive Heating

The Ino Trident’s inductive heating technology introduces several notable benefits that elevate both the efficiency and quality of 3D printing processes:

- Improved Support Structures: The rapid cooling enabled by the inductive system minimizes sagging in bridges and enhances the quality of bottom surfaces, even in prints without support structures.

- Seamless Variable Temperature Printing: Quick temperature changes during a print allow for smoother transitions between materials or layers, reducing imperfections and improving surface finishes.

- Enhanced Filament Heating Efficiency: Precise and consistent heating ensures reliable extrusion, particularly for filaments that require tight temperature tolerances, such as advanced engineering materials.

These features make the Ino Trident a compelling choice for users aiming to push the boundaries of what’s achievable in 3D printing, offering both practical benefits and creative possibilities.

World’s First INDUCTIVE Hotend for 3D printing

Browse through more resources below from our in-depth content covering more areas on 3D printing :

Performance Insights and Early Testing

Early testing of the Ino Trident revealed performance comparable to established hotends like the E3D V6 in standard printing scenarios. However, its true strengths became evident in more demanding applications, such as variable temperature control and intricate geometries. For instance, prints with complex support structures and detailed designs demonstrated noticeable improvements in surface quality and dimensional accuracy.

Firmware updates have addressed initial challenges with rapid temperature changes, further enhancing the hotend’s reliability. Despite these advancements, some limitations were observed during testing. At higher flow rates, uneven filament heating occasionally disrupted extrusion consistency. Additionally, the lack of slicer software support for advanced temperature control required users to manually adjust gcode, complicating workflows for those unfamiliar with such processes.

Challenges and Areas for Development

While the Ino Trident represents a significant leap forward in hotend technology, several challenges must be addressed to ensure its widespread adoption and usability:

- Slicer Software Compatibility: Current slicer software does not natively support the hotend’s variable temperature capabilities, requiring manual adjustments that may deter less experienced users.

- Filament Heating Consistency: At higher flow rates, the heat block design could benefit from refinements to ensure uniform extrusion and consistent performance across all conditions.

- Workflow Simplification: Streamlining the process of implementing temperature-controlled printing would make the technology more accessible to a broader range of users, from hobbyists to professionals.

Addressing these challenges will be critical for unlocking the full potential of inductive hotends and making sure their seamless integration into mainstream 3D printing workflows.

Future Potential and Industry Impact

The Ino Trident’s innovative approach to temperature control holds significant promise for specialized 3D printing applications. Its ability to produce support-free bottom surfaces through precise temperature management could transform how complex designs are approached. As slicer software and firmware continue to evolve, the hotend’s capabilities could expand further, making it an invaluable tool for both hobbyists and professionals seeking to achieve greater precision and efficiency.

Looking ahead, the Ino Trident has the potential to set new industry standards for hotend performance and energy efficiency. By addressing current limitations and integrating seamlessly with existing workflows, it could pave the way for more advanced, versatile, and accessible 3D printing solutions. This innovation not only enhances the technical capabilities of 3D printers but also enables users to explore new creative and functional possibilities in their projects. Jump over to the Plasmics website for full specifications, information and world pricing.

Media Credit: PRINTING PERSPECTIVE

Filed Under: Design News, Technology News, Top News

Latest TechMehow Deals

Disclosure: Some of our articles include affiliate links. If you buy something through one of these links, TechMehow may earn an affiliate commission. Learn about our Disclosure Policy.